Camshafts are made of steel and cast iron. The starting material of the steel cams is the rod material, then precisely machined and inductively hardened on the surface, respectively case-hardened. Cast iron shafts are produced by casting an iron alloy. The steel material used for the production of camshafts differs from the cast iron by the structure of the material, especially the carbon content – max. 2.11%. Above this carbon limit we are already talking about cast iron.

TIP: Learn what risks are caused by not following the correct procedures when doing cam replacement and how they can be prevented.

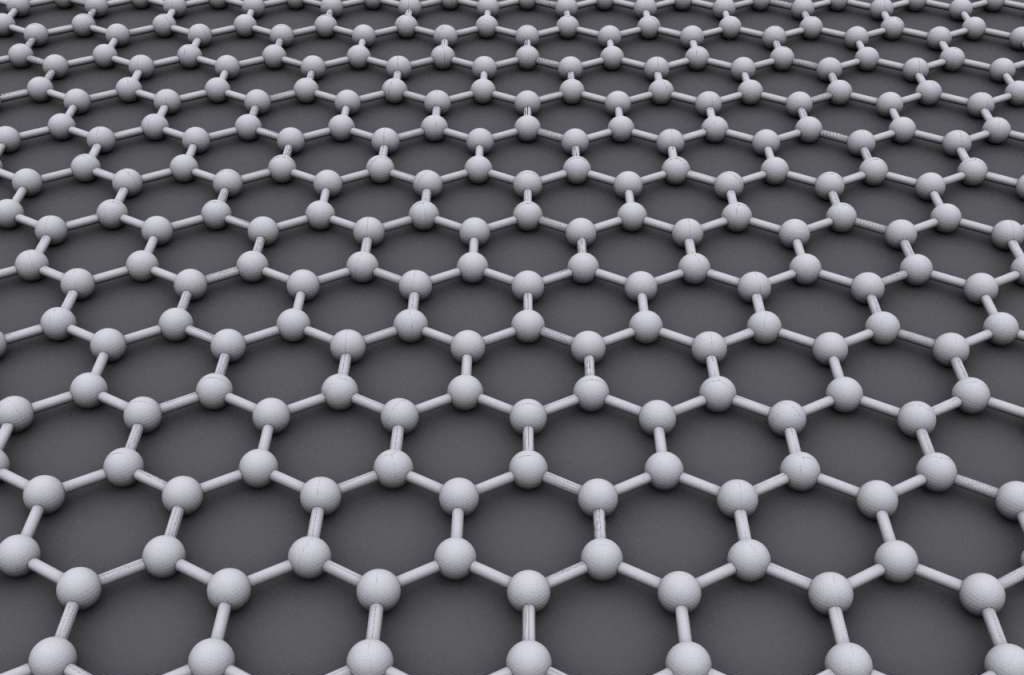

Both material differ in the structure, respectively by arranging atoms in the crystal lattice and thus by various toughness and hardness. The production of camshafts is challenging for accuracy. Inspection of geometric shapes of camshafts is done by laser measurement. Steel camshafts handle more mechanical loads than cast iron camshafts and are comparable to OE camshafts. Camshafts of hardened cast iron have a harder surface, however, this does not mean that they should necessarily have shorter lifetime. Their production is less costly and they are also cheaper for the aftermarket. If you follow the correct procedure for disassembly and replacement of camshaft, it is possible to replace steel cams in certain types of engines with cast iron cams.